Conducere

Investing in Aerospace to Meet Customer Demand

The aerospace industry is booming, with growth across commercial, defense, rotorcraft and space applications. GE Aerospace, which supplies engines for Boeing and Airbus, is set to invest $1 billion in U.S. manufacturing in 2025.

“The world is more global, and aerospace is what connects us all, whether that be with satellites that bring the internet to remote places, or aircraft that fly us physically around the world,” says Erin Amarello, aerospace business manager.

Amarello leads a cross-functional team focused on growth in Timken’s aerospace business. “We see a steep rise in demand for aerospace solutions,” she says. “We’re focused on helping customers meet that demand — investing in facilities, technology and the supply chain so we can meet them with our capacity as they ramp up theirs.”

Timken investments help keep aerospace customers on the leading edge in every sector:

Commercial

Rotorcraft

Space

Multi-sector growth

Timken has a long history in aerospace and today, aircraft passengers around the world rely on Timken landing wheel bearings to get them safely back on solid ground. After a decline, commercial air travel is back to pre-COVID levels and rising. COVID was the catalyst for skyrocketing satellite and internet technology, as people supplemented physical connections with virtual ones, and that trend continues.

“More countries are going to space today, more are sending up satellites, the middle class around the world is growing, and all those factors drive aerospace growth,” says Amarello. Countries around the world are also more concerned about the safety of their borders, which brings an increased focus on defense and rotorcraft applications.

“While our customers are the experts on engines, aircraft, helicopters and satellites — we’re the experts on bearings.”

Erin Amarello, Business Manager – Aerospace

A strategic focus on aerospace

Amarello’s aerospace team brings leaders together from across Timken’s manufacturing facilities, as well as design and applications engineers, product pipeline, global sales, quality and customer service. Individual aerospace-focused Timken businesses, such Aurora Bearing, GGB and Bii, also have a presence.

“Increasing our investments in aerospace and hitting these aggressive growth targets requires cross-functional alignment,” she says. “We’re creating a unified vision, developing long-term strategies, and making sure we’re all moving in the same direction.”

Timken’s investments in aerospace over the past decade are already helping customers transform their industries. Acquired businesses, such as GGB and Aurora, have broadened Timken’s product portfolio and expertise, and new ceramic hybrid roller bearing product lines are playing a central role in next-generation aircraft designs.

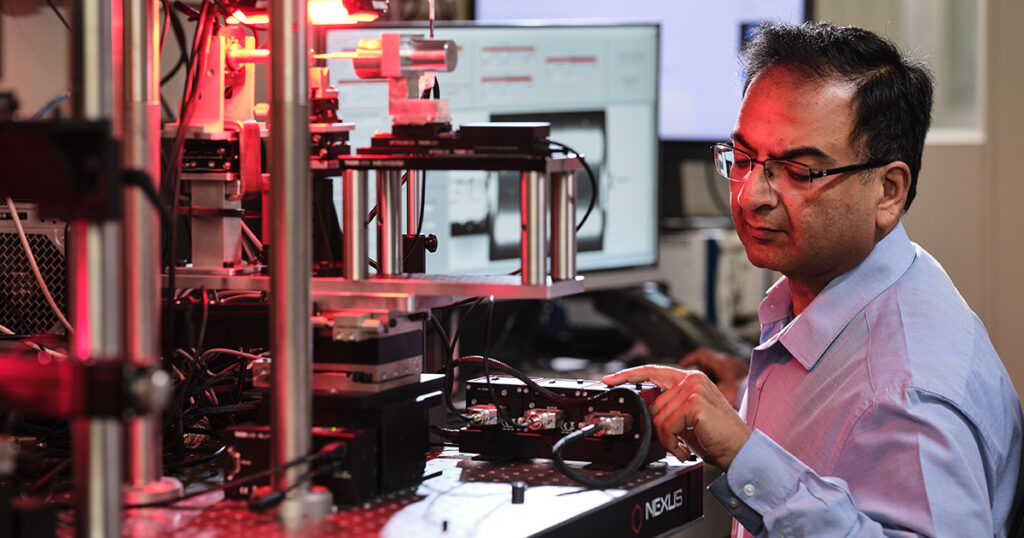

Ashish Vasil, Manager, Manufacturing R&D, reviews ceramic rollers on a state-of-the-art test rig.

Upholding the fundamentals: quality + engineering expertise

As Timken evolves its legacy of leadership in aerospace, engineers across all market sectors are working with customers to develop next-gen platforms. “While our customers are the experts on engines, aircraft, helicopters, defense applications and satellites — we’re the experts on bearings,” says Amarello.

Aerospace customers come to Timken for engineering expertise and for unrivaled quality. “Our bearings have to work the way they’re intended to,” says Amarello. “People’s lives depend on these applications.”

One project she won’t forget is working on a set of bearings for the most recent NOAA satellite. “They were very difficult to produce — if you breathed on them, they would get rejected,” she quips. “It was a reminder that the things we make — they’re important to how the world works, and people’s safety.”

As Amarello and her team continue their effort to ramp up aerospace capacity, customers can be sure that every bearing will meet the highest standards in the business. “Aerospace is ideal for me because with these products, it’s so easy to understand why what I do matters,” she says.

Timken’s prototyping shop helps R&D engineers prove that new designs can be manufactured successfully, shortening delivery times for many aerospace solutions. Read more.

Last Updated: 2025/07/16

Published: 2025/07/15