Understanding Pillow Block Bearing Assembly: A Comprehensive Guide to Applications and Maintenance

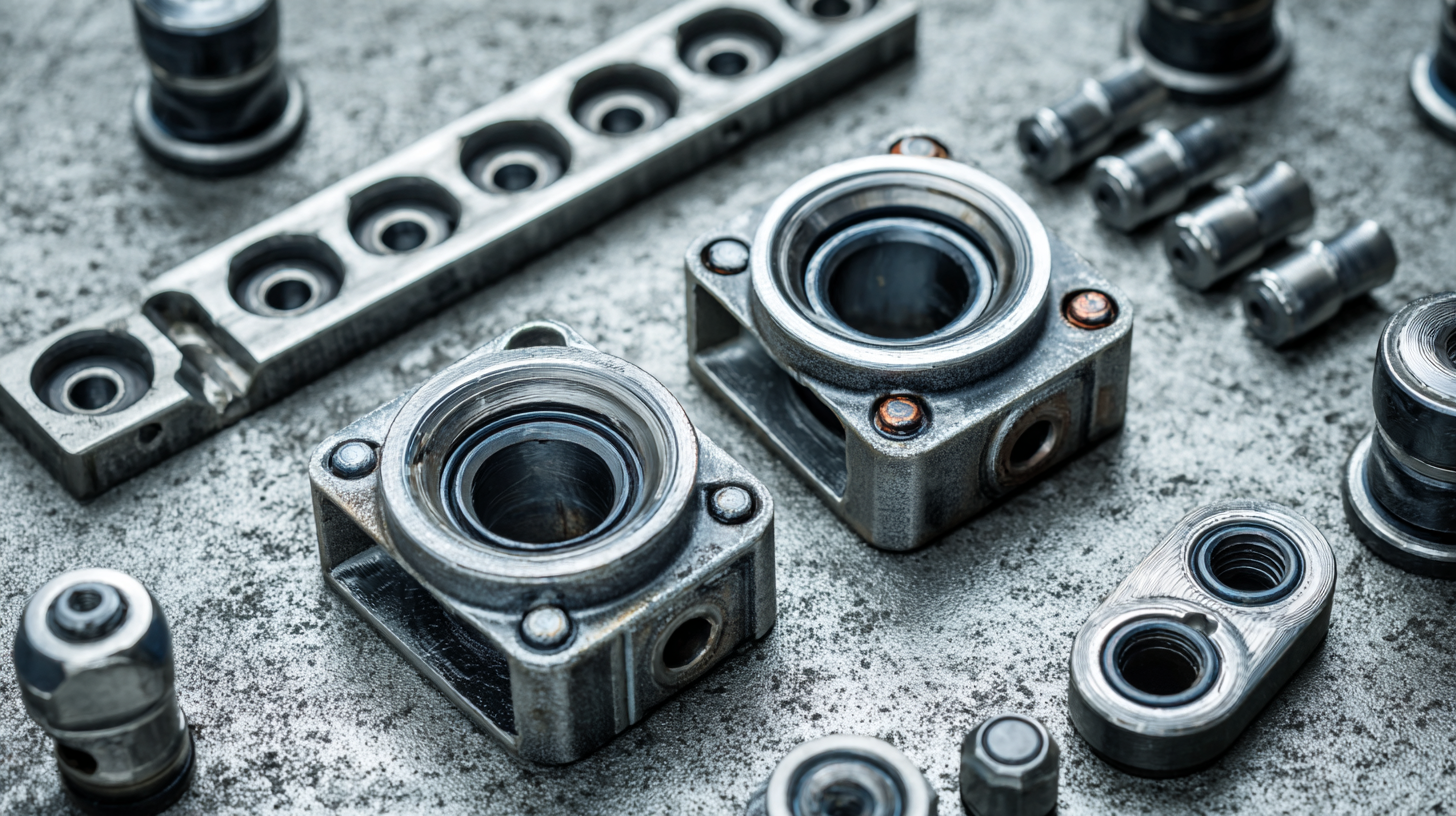

In the world of mechanical engineering, the pillow block bearing assembly plays a crucial role in various applications, providing essential support and stability for rotating shafts. This robust assembly consists of a bearing housed within a block that can be easily mounted on a base, allowing for efficient alignment and maintenance. Understanding the intricacies of pillow block bearing assemblies is vital for engineers and technicians alike, as it directly impacts the longevity and performance of machinery.

In the world of mechanical engineering, the pillow block bearing assembly plays a crucial role in various applications, providing essential support and stability for rotating shafts. This robust assembly consists of a bearing housed within a block that can be easily mounted on a base, allowing for efficient alignment and maintenance. Understanding the intricacies of pillow block bearing assemblies is vital for engineers and technicians alike, as it directly impacts the longevity and performance of machinery.

This comprehensive guide delves into the types of pillow block bearing assemblies available, their applications across different industries, and best practices for maintenance to ensure optimal functionality. By exploring these elements, readers will gain valuable insights into selecting the right type of assembly for their specific needs and maintaining it effectively, ultimately enhancing operational efficiency and reducing downtime.

How to Identify the Right Pillow Block Bearing for Your Application

When selecting the right pillow block bearing for your application, it's essential to consider several critical factors. First, assess the load requirements of your machinery. Pillow block bearings must support both radial and axial loads, so understanding the specific load conditions your application will face is crucial. This information will guide you in choosing a bearing that can withstand the operational demands without premature wear or failure.

Next, evaluate the environmental conditions in which the pillow block bearings will operate. Factors such as temperature fluctuations, exposure to moisture, or contamination from dust and debris can significantly impact the bearing's performance and lifespan. Selecting a bearing with appropriate seals and materials tailored for your operating environment can enhance durability and reduce maintenance needs. Additionally, reviewing the bearing housing configuration and dimensions ensures compatibility with your existing setup, promoting optimal alignment and performance throughout its service life.

Understanding Pillow Block Bearing Applications and Maintenance

How to Properly Install a Pillow Block Bearing Assembly

When it comes to the installation of a pillow block bearing assembly, precision and adherence to best practices are essential to ensure optimal performance and longevity. Proper installation not only reduces the risk of premature wear but also enhances the overall functionality of machinery that relies on these components. Research indicates that improper alignment can lead to load imbalances, which may cause a decrease in service life by up to 30% according to industry experts. Therefore, understanding the correct procedures is crucial.

Firstly, start by meticulously preparing the installation site. Ensure that the mounting surface is clean and free from debris, and that the housing is properly supported. It is vital to securely fasten the pillow block bearings using the specified torque settings to avoid any loosening during operation. Additionally, a correct initial alignment of the shaft with the pillow block is paramount to minimize stress on the bearings; misalignment can be detected using laser alignment tools, ensuring precision to within one thousandth of an inch.

Moreover, regular maintenance checks are indispensable for the longevity of pillow block bearings. Data shows that routine inspections can reveal early signs of wear or misalignment, which, if addressed promptly, can prevent more extensive damage. A proactive maintenance regime, including timely lubrication and monitoring of operational temperatures, can extend the life of these assemblies significantly, potentially doubling their expected service life in critical applications. Maintaining best practices in installation and upkeep can lead to enhanced reliability, maximizing the efficiency of the associated machinery.

How to Conduct Routine Maintenance on Pillow Block Bearings

Routine maintenance of pillow block bearings is essential for ensuring their longevity and optimal performance. One key aspect of maintenance is regular lubrication. It is crucial to check the lubricant level frequently and apply the appropriate type of grease or oil as specified by the manufacturer. Over-lubrication or under-lubrication can both lead to premature failure, so achieving the right balance is vital. In addition to lubrication, inspecting the condition of seals and shields can prevent contaminants from entering the bearing, which could compromise its functionality.

Another important maintenance practice involves regular inspection of the bearing housing and mounting. Ensure that all bolts are tightened to the recommended torque specifications to avoid misalignment or excessive vibration. It’s also advisable to monitor the operating temperature of the bearing during use. Elevated temperatures may indicate underlying issues such as insufficient lubrication, misalignment, or bearing wear. By implementing these routine checks and maintenance tasks, operators can extend the life of pillow block bearings and enhance the reliability of their machinery.

Understanding Pillow Block Bearing Assembly: A Comprehensive Guide to Applications and Maintenance

| Dimension |

Specification |

Material |

Application |

Maintenance Frequency |

| 1 inch |

B89-1 |

Cast Iron |

Agricultural Machinery |

Every 6 months |

| 2 inch |

B89-2 |

Stainless Steel |

Food Processing |

Every 3 months |

| 3 inch |

B89-3 |

Polymer |

Textile Industry |

Every 1 year |

| 4 inch |

B89-4 |

Aluminum |

Automotive |

Every 2 months |

How to Troubleshoot Common Issues with Pillow Block Bearing Assemblies

Pillow block bearing assemblies are essential components in many mechanical systems, providing support and enabling smooth rotation of shafts. However, like any mechanical assembly, they can encounter issues over time. Common problems include excessive noise, overheating, and misalignment. To troubleshoot these issues effectively, it's crucial to first identify the specific symptoms. For instance, if the assembly is making unusual noises, it may indicate insufficient lubrication or worn-out bearings that need replacement.

Another common issue is overheating, which can stem from poor alignment or overloading of the shaft. Regular inspections for proper alignment and checking whether the load parameters are within the design specifications can help prevent this problem. Furthermore, ensuring adequate lubrication is vital, as insufficient grease can lead to increased friction and subsequent overheating. In cases of misalignment, adjustments should be made carefully to restore proper positioning and functionality. By addressing these issues proactively, you can significantly extend the lifespan of your pillow block bearing assemblies and ensure optimal performance.

How to Replace a Pillow Block Bearing Safely and Effectively

Replacing a pillow block bearing can significantly enhance the performance and lifespan of machinery. To start, ensure safety by disconnecting power sources and securing the equipment to prevent any movement during the process.

Begin by removing any guards or shielding that obstruct access to the bearing assembly. Use appropriate tools to unfasten the mounting bolts and carefully extract the old pillow block bearing from its housing.

Once the old bearing is removed, inspect the shaft for any signs of wear or damage before installing the new bearing. Clean the housing thoroughly to eliminate any debris or old lubricant, which can affect the performance of the new bearing.

When installing the new pillow block bearing, ensure it is aligned properly and secured tightly with the mounting bolts.

After reassembling any guards, restore power to the machine and perform a test run to confirm that everything operates smoothly and without any unusual noises. Regular maintenance checks should follow to ensure that the new bearing remains in optimal condition.