Innovative Solutions for Optimizing Roller Bearings Performance

In today's fast-paced industrial landscape, the performance of roller bearings plays a crucial role in ensuring the efficiency and longevity of machinery across various applications. As critical components that support rotating shafts, roller bearings must endure significant loads while minimizing friction and wear. However, traditional designs often face limitations in terms of durability and operational efficiency. This blog explores innovative solutions for optimizing roller bearings performance, highlighting cutting-edge materials, advanced manufacturing techniques, and insightful design modifications that can significantly enhance their functionality. By embracing these solutions, industries can not only improve the reliability of their systems but also reduce maintenance costs and downtime, ultimately leading to a more sustainable and productive operation. Join us as we delve into the future of roller bearings and the transformative approaches that redefine their capabilities.

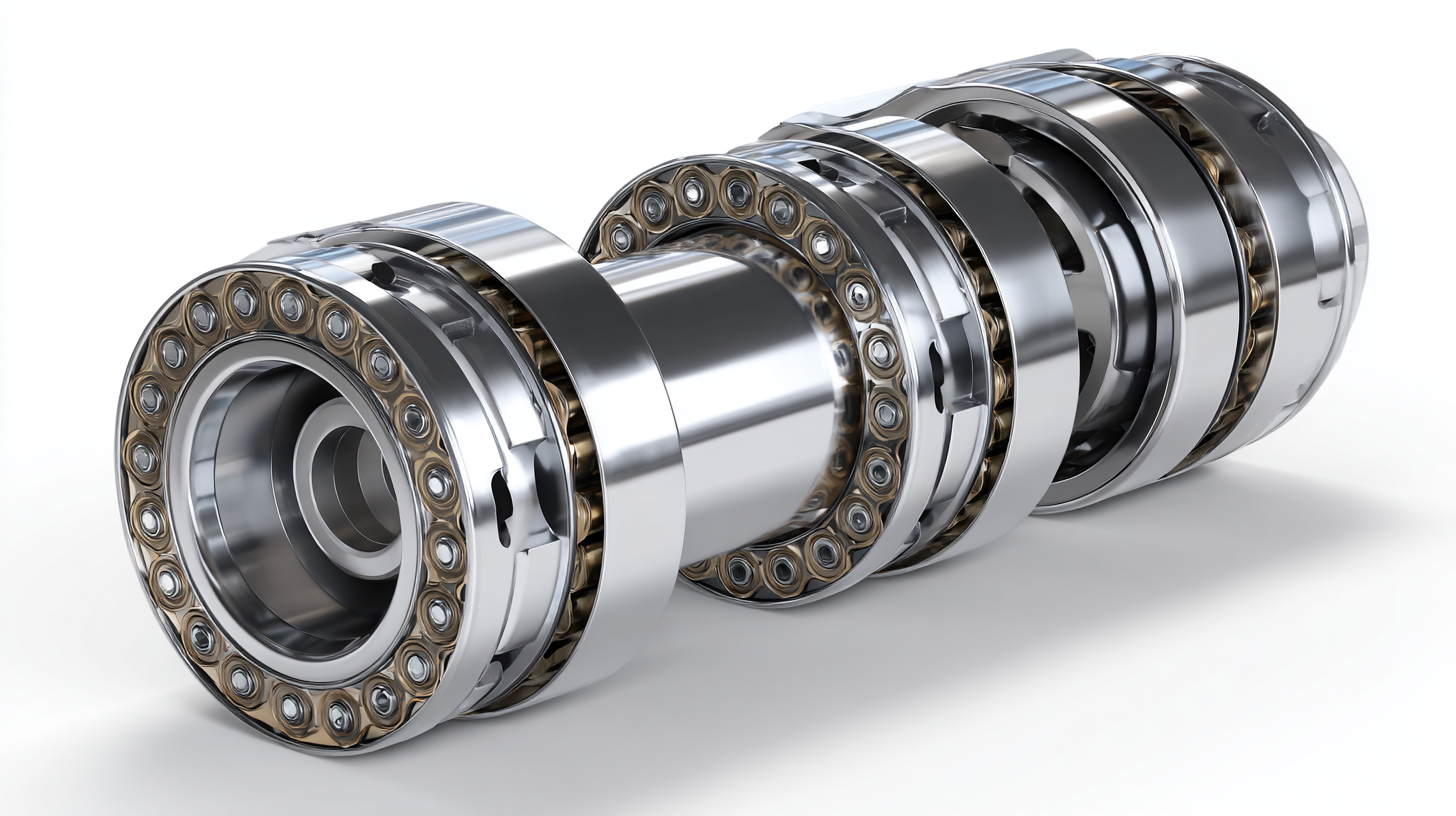

Innovative Technologies Revolutionizing Roller Bearings Efficiency

The efficiency of roller bearings is undergoing a significant transformation due to innovative technologies that are revolutionizing performance standards across various industries. Recent data from the Global Bearing Market report highlights a projected growth rate of 8% annually for advanced bearing solutions through 2025. This surge is largely driven by the adoption of specialized materials such as ceramic composites and advanced metallic alloys, which enhance durability and reduce friction, thereby extending service lifespan and improving overall efficiency.

Incorporating smart technology into roller bearings is also a game-changer. Sensors embedded within bearings allow for real-time monitoring of performance metrics, enabling predictive maintenance that minimizes downtime. According to a study published by the International Journal of Precision Engineering and Manufacturing, companies employing such smart bearings have reported up to a 30% reduction in maintenance costs and a 20% increase in operational efficiency. As industries strive for greater productivity and sustainability, these innovative solutions are key to maximizing the performance of roller bearings and driving future advancements in machinery design.

Key Factors Influencing Roller Bearings Durability and Performance

Roller bearings play a crucial role in the efficiency and longevity of machinery across various industries. Their durability and performance are significantly affected by several key factors, including load capacity, operating conditions, lubrication, and material selection. According to a recent industry report by the International Organization for Standardization, nearly 30% of all bearing failures are attributed to improper lubrication. This highlights the paramount importance of selecting the right lubricant and maintaining a consistent lubrication schedule to enhance bearing life.

Tips: Always evaluate the operating conditions and select lubricants that can withstand the expected temperatures and loads. Regularly scheduled maintenance checks can also prevent unexpected failures and prolong the lifespan of roller bearings.

Another critical factor influencing roller bearing performance is material selection. Advanced materials, such as ceramic or hybrid bearings, can offer reduced friction and increased resistance to wear and corrosion, potentially extending bearing life by up to 50%. As the report from Bearing Specialists Association suggests, the implementation of advanced materials could yield significant cost savings in both maintenance and operational downtime.

Tips: Invest in quality materials for your roller bearings that match your specific application requirements. Performance testing and simulation can help in understanding the best material choices for your unique operational needs.

Data-Driven Approaches for Enhanced Roller Bearings Reliability

In the realm of industrial machinery, ensuring the reliability of roller bearings is paramount. Leveraging data-driven approaches can significantly enhance their performance, allowing for predictive maintenance and timely fault diagnosis. Recent advancements, such as a novel bearing fault diagnosis method utilizing conditional diffusion models, demonstrate how differential out-of-distribution error guidance can identify faults even in unknown conditions. This technique represents a sturdy evolution in reliably assessing bearing health, offering a more robust framework in unpredictable environments.

When implementing these data-driven solutions, consider the following tips. First, integrate multiple machine learning algorithms to capitalize on their collective strengths. This hybrid approach ensures more accurate predictions and analysis of bearing capacity. Secondly, adopting generative adversarial networks for sample enhancement can effectively tackle the challenges posed by limited and noisy datasets typical in operational settings. By enhancing the quality of vibration data, you enable a more precise reliability evaluation.

Incorporating intelligent fault diagnosis models that utilize hyperparameter tuning can also facilitate effective monitoring under various operating conditions. This adaptability is crucial, given the complexities of changing environments that equipment often faces. By staying ahead of potential issues, organizations can optimize the performance and longevity of roller bearings, propelling their operations toward greater efficiency.

Top Design Practices to Maximize Roller Bearings Functionality

When aiming to maximize roller bearings functionality, design practices play a crucial role in their performance and longevity. One key consideration is the selection of materials. Using high-quality steel or advanced ceramic materials can significantly enhance durability and resistance to wear, which in turn improves operational efficiency. Additionally, incorporating surface treatments such as coatings can reduce friction and increase the bearings' ability to operate under extreme conditions, thereby extending their service life.

Another essential design practice involves precise lubrication strategies. Implementing appropriate lubrication systems based on the application's specific requirements ensures that roller bearings remain well-lubricated, reducing overheating and wear. Adaptive lubrication systems can further optimize performance by adjusting the lubricant flow according to real-time operational conditions. Furthermore, attention to alignment and installation techniques is paramount, as even slight misalignments can lead to premature failure. By adopting these top design practices, engineers can significantly enhance the functionality and reliability of roller bearings in various applications.

Future Trends in Roller Bearings Optimization: What to Expect

As the demand for high performance and efficiency continues to grow in various industrial applications, the optimization of roller bearings is becoming increasingly critical. Future trends in roller bearings optimization will center around advanced materials technology and smart manufacturing processes. Innovations such as the use of composite materials aim to reduce weight while enhancing load capacity and durability.

Additionally, the introduction of self-lubricating bearings can improve efficiency and reduce maintenance downtime, leading to longer service life and better performance in extreme conditions.

Another significant trend is the integration of digital technologies such as IoT and machine learning. These technologies facilitate real-time monitoring and predictive maintenance, enabling manufacturers to anticipate failures before they occur. By harnessing big data analytics, organizations will be able to optimize their lubrication strategies and operational parameters, enhancing the overall efficiency of roller bearings. As industries increasingly adopt these innovations, we can expect a paradigm shift towards more intelligent, efficient, and sustainable bearing solutions that meet the evolving needs of modern engineering applications.