Understanding the Industry Standards Behind the Best Needle Roller Bearings and Why They Matter

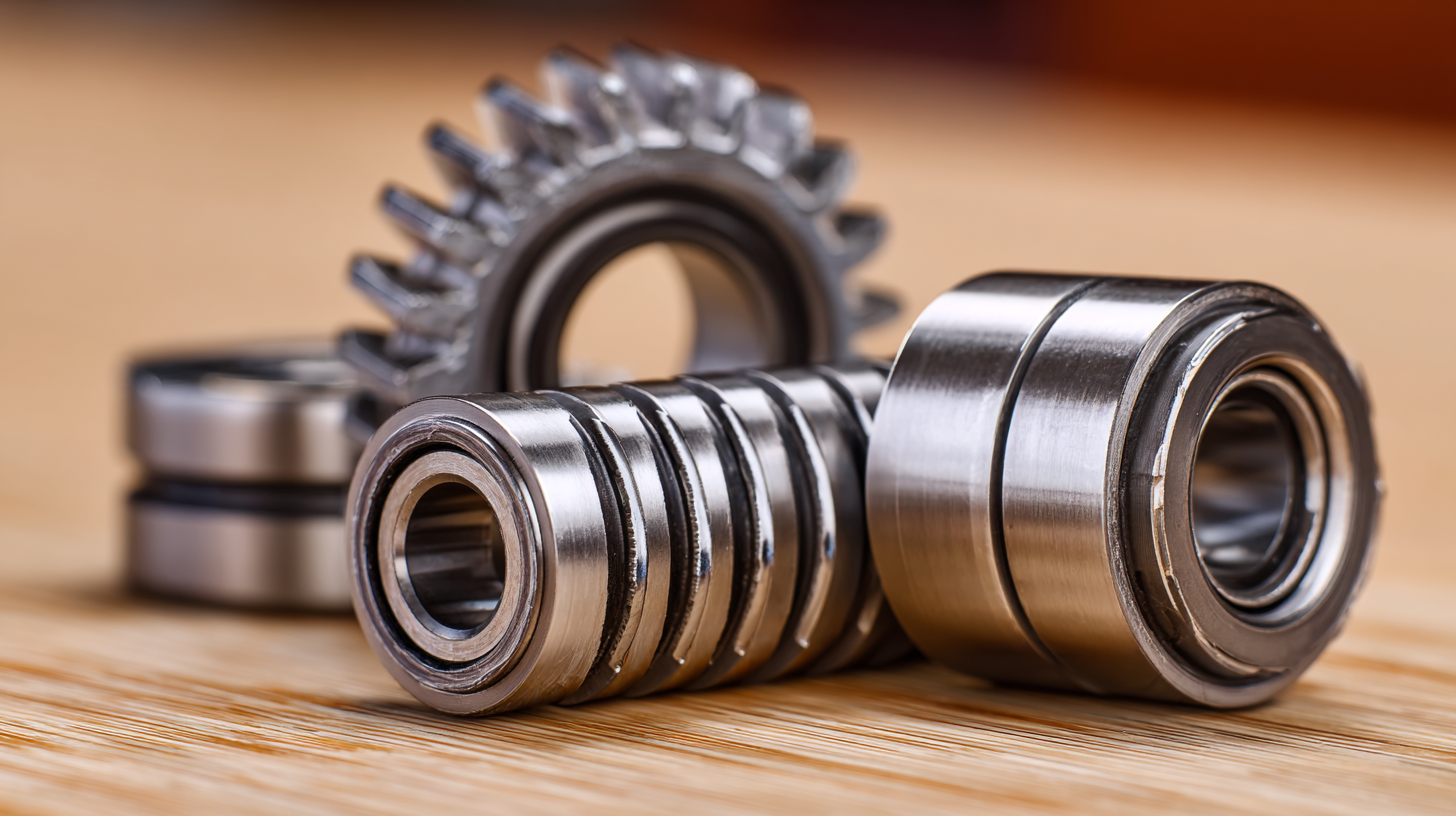

In the world of mechanical engineering, the significance of selecting high-quality needle roller bearings cannot be overstated. These compact and efficient components play a crucial role in reducing friction and enhancing the performance of various machinery and automotive applications. However, the sheer variety of suppliers and products available in the market can make it challenging for engineers and procurement professionals to identify the best options.

This blog aims to provide a comprehensive guide on the industry standards that define top-tier needle roller bearings, emphasizing the key factors to consider when searching for a reliable supplier. By understanding these standards and their implications, businesses can ensure they select needle roller bearings that not only meet their operational needs but also contribute to the longevity and efficiency of their equipment.

Key Industry Standards Defining Needle Roller Bearing Performance and Quality

When discussing the performance and quality of needle roller bearings, it’s crucial to highlight the industry standards that govern their manufacturing and application. These standards are not only benchmarks for quality but also ensure that products meet the necessary specifications for various industries. The needle roller bearing market, a significant segment of the global bearings market, was valued at over USD 2.9 billion in 2023 and is projected to grow at a CAGR of approximately 6.5% from 2024 to 2032. This growth reflects the increasing demand for high-performance bearings in automotive and other applications, underlining the importance of adhering to defined industry standards.

Specific standards emphasize various performance metrics, including load ratings, durability, and operating conditions. For instance, ISO and ASTM standards provide comprehensive guidelines for testing the mechanical properties and tolerances of needle roller bearings. As the overall bearings market size is anticipated to increase from USD 162.57 billion in 2024 to USD 241.62 billion by 2033, these standards will play a critical role in ensuring that manufacturers can deliver consistent quality and performance. Companies that prioritize compliance with these industry standards are positioned to excel in a competitive marketplace, driving innovation and reliability in bearing technology.

Understanding the Industry Standards Behind the Best Needle Roller Bearings and Why They Matter

| Standard |

Description |

Application |

Impact on Performance |

| ISO 4026 |

Standard defining tolerances for needle roller bearings. |

Automotive, industrial machinery |

Ensures consistent fit and performance in assemblies. |

| DIN 618 |

Metric standard for roller bearings with specifications on dimensions and performance. |

Heavy machinery, construction equipment |

Improves load capacity and service life. |

| ABEC 1-9 |

Annular bearing performance evaluation criteria for tolerances. |

Precision machinery, robotics |

Directly correlates to precision and efficiency of motion. |

| ASTM F2079 |

Standard test method for measuring the performance characteristics of needle roller bearings. |

Aerospace, automotive engine components |

Ensures reliability under extreme conditions. |

Impact of Material Selection on Needle Roller Bearing Durability and Functionality

The durability and functionality of needle roller bearings are significantly influenced by the materials selected for their construction. In industries such as aerospace, where performance and reliability are paramount, the right material can mitigate issues like Rolling Contact Fatigue (RCF) and fretting, which often leads to severe damage over time. Reports indicate that RCF, resulting from cyclic stresses during bearing operation, can lead to catastrophic failures if not addressed properly. The choice of high-quality materials, such as advanced steel alloys or composites, can enhance wear resistance and extend the service life of these critical components.

Moreover, fretting corrosion, often referred to as false brinelling, is another major concern for needle roller bearings, particularly in high-vibration environments. Studies have shown that implementing coatings or surface treatments can dramatically reduce fretting damage by providing a barrier against wear and corrosive elements. Data reflects a significant improvement in bearing longevity when using enhanced material selections, showcasing a potential increase in lifespan by up to 50% compared to standard materials. Thus, understanding the impact of material selection is essential for optimizing needle roller bearing performance in demanding applications.

Impact of Material Selection on Needle Roller Bearing Durability and Functionality

Critical Load Ratings: Understanding Bearing Metrics and Their Real-World Applications

When choosing needle roller bearings, understanding critical load ratings is paramount. These ratings help determine how much load a bearing can handle without experiencing failure, ensuring that your machinery operates smoothly and effectively. The load ratings are classified into dynamic and static load ratings, which provide insights into the bearing's performance under different conditions. This knowledge is essential for selecting the right bearing for specific applications, particularly in industries like automotive, aerospace, and manufacturing.

Tip: Always consult the manufacturer's specifications for load ratings and ensure they align with the intended application. This can prevent premature bearing wear and potential equipment breakdowns.

Real-world applications of load ratings can be seen across various sectors. For example, in automotive applications, bearings must endure high dynamic loads due to constant acceleration and deceleration. Knowing the dynamic load rating allows engineers to choose bearings that will withstand these forces while maximizing lifespan and reliability. Likewise, static load ratings are crucial in situations where the bearing is subjected to stationary loads, helping to avoid deformation or failure.

Tip: Consider the operating environment when assessing load ratings, as factors like temperature, lubrication, and contamination can significantly impact performance.

The Role of Precision Manufacturing Processes in Achieving Optimal Bearing Efficiency

Precision manufacturing processes are the backbone of high-quality needle roller bearings, ensuring that every component meets stringent industry standards. These bearings, commonly used in applications requiring low friction and high load capacity, necessitate exacting tolerances and meticulous craftsmanship. During the manufacturing process, techniques such as CNC machining, heat treatment, and precision grinding are employed to shape the inner and outer races, rollers, and cage, allowing for seamless operation and extended service life.

Moreover, quality assurance measures, including rigorous testing and inspection protocols, play a critical role in maintaining consistency and reliability. By leveraging advanced technology and methodologies, manufacturers can detect imperfections at a microscopic level, which is essential for ensuring optimal bearing performance under various operational conditions. The focus on precision not only enhances the bearings' efficiency but also significantly reduces the risk of failure in complex machinery, boosting overall productivity. Advanced manufacturing also allows for the customization of bearings to meet specific requirements, further elevating their performance in industry applications.

Recent Innovations and Trends Shaping the Future of Needle Roller Bearings in Industries

Recent innovations in needle roller bearings are significantly influencing various industries, fueled by advancements in material science and manufacturing processes. As the global bearings market continues to expand, projected to reach USD 97.10 billion, the introduction of nanomaterials and new techniques is enhancing the performance and durability of these essential components. Companies are increasingly focusing on integrating high-strength materials and smart technologies to meet the growing demands of modern applications, including automotive and railway systems.

Moreover, the trend towards sustainability is guiding the evolution of needle roller bearings. Manufacturers are exploring laser-based technologies and additive manufacturing to create more efficient and effective designs that reduce waste and optimize performance. As the industry embraces these cutting-edge methods, it not only boosts productivity but also aligns with the global push for greener solutions. This convergence of innovation and sustainability is set to shape the future of needle roller bearings, ensuring they meet the rigorous standards of the industries they serve.