Future Technologies Shaping Best Precision Bearings for Global Buyers by 2025

In the rapidly evolving landscape of manufacturing and engineering, the demand for high-quality precision bearings is anticipated to surge, driven by advancements in technology and increased global competition. According to a recent report from MarketsandMarkets, the precision bearings market is expected to reach USD 85.75 billion by 2025, growing at a CAGR of 6.76% from 2020. This growth is propelled by the expanding automotive, aerospace, and industrial machinery sectors, where the role of precision bearings is crucial for enhancing performance and reducing operational costs. As we look toward 2025, innovations in smart materials and manufacturing processes are set to redefine the standards of precision bearings, providing solutions that meet the stringent requirements of global buyers while optimizing efficiency and reliability. This blog will explore the key technological trends shaping the future of precision bearings and their implications for industries worldwide.

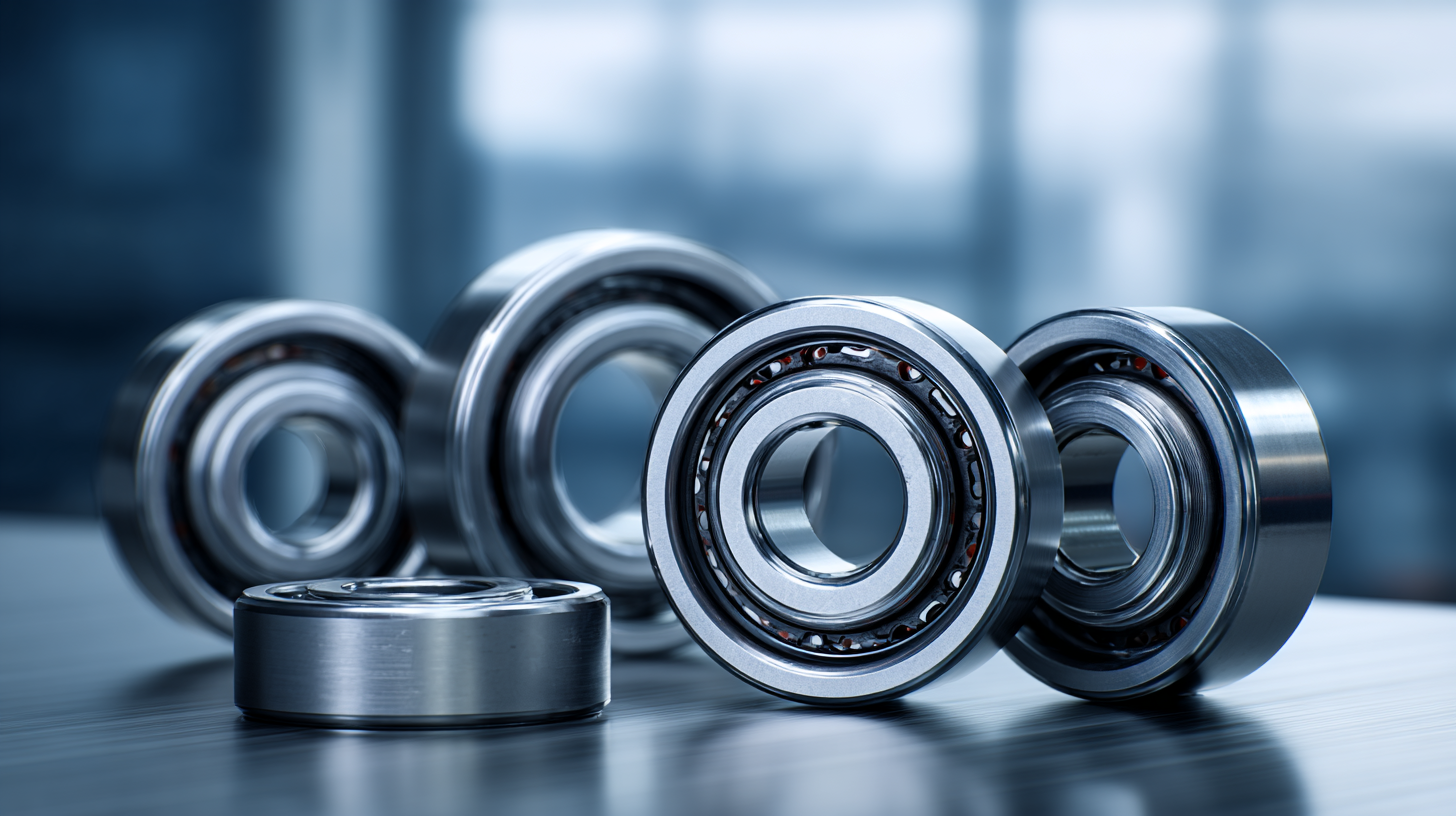

Advancements in Materials: The Next Generation of Precision Bearings

The landscape of precision bearings is evolving rapidly due to significant advancements in materials. By 2025, we can expect the introduction of next-generation precision bearings that leverage innovative materials like ceramic composites and advanced polymers. According to a report from Allied Market Research, the global precision bearings market is projected to reach $22.43 billion by 2025, driven by increasing demand in industries such as aerospace, automotive, and manufacturing. These materials not only enhance the performance and lifespan of bearings but also reduce weight and energy consumption, making them ideal for high-performance applications.

Tips for buyers looking to invest in precision bearings include focusing on suppliers who prioritize material innovation and sustainability. Look for bearings made from high-performance ceramics, which offer superior load capacity and corrosion resistance, or advanced polymers that can withstand extreme temperatures and harsh environments. Additionally, consider the role of lubrication technology in maximizing bearing efficiency; high-quality lubricants can drastically extend the service life of bearings and reduce maintenance costs.

As manufacturers continue to adapt to stringent regulatory standards and environmental challenges, investing in next-generation precision bearings will become not just a technological upgrade, but a critical strategy for maintaining competitive advantage. Understanding the materials landscape will empower global buyers to make informed decisions that align with evolving industry standards and sustainability goals.

The Role of AI and Automation in Precision Bearing Manufacturing

The integration of AI and automation is revolutionizing the manufacturing landscape of precision bearings, propelling advancements that cater to global buyers by 2025. As industries increasingly demand higher efficiency and precision, artificial intelligence facilitates predictive maintenance and quality control, reducing waste and enhancing production reliability. Automation streamlines the manufacturing process, allowing for faster production times and lower labor costs, which is crucial in meeting the demands of a competitive global market.

Tip: When considering investments in precision bearing manufacturers, pay attention to those adopting AI-driven technologies. Companies that leverage automation are likely to maintain a competitive edge by minimizing downtime and optimizing their supply chains.

Furthermore, as robots become an integral part of manufacturing, the synergy between machine learning and robotics enhances the production of precision components. This transformation not only increases productivity but also ensures better quality assurance, positioning manufacturers to meet the exacting standards of buyers worldwide.

Tip: Keep an eye on how companies integrate robotic solutions in their operations, as this will likely be a key differentiator in the market. Support businesses that are innovating with robotics and AI, as they will likely shape the future of precision bearing manufacturing.

Market Trends: Demand for High-Performance Bearings in Diverse Industries

The increasing demand for high-performance bearings across various industries signals a significant shift in manufacturing and technology. With advancements in materials science and engineering, industries such as automotive, aerospace, and renewable energy are prioritizing bearings that can withstand extreme conditions while improving efficiency. These high-performance bearings are designed to reduce friction, enhance load capacity, and prolong service life, which is essential as global companies strive for greater sustainability and cost-effectiveness.

As markets evolve, several key trends are emerging. The rise of electric vehicles is driving a need for lightweight, durable bearings that support advanced drivetrains and energy-efficient systems. Similarly, the aerospace sector is focusing on bearings that can handle higher speeds and loads, ensuring safety and reliability in flight. Additionally, the renewable energy sector, particularly wind and solar, requires robust bearings that can operate in harsh environmental conditions. As these industries continue to expand, manufacturers are encouraged to innovate and adapt their product offerings to meet the growing requirements of high-performance bearings worldwide.

Sustainability in Bearing Production: Innovations and Future Prospects

Sustainability is increasingly becoming a pivotal consideration in the production of precision bearings, driven by both regulatory pressures and consumer demand for environmentally friendly practices. Innovations in materials science are introducing biodegradable and recyclable materials that minimize the ecological footprint of bearing production.

For instance, the development of advanced composites not only maintains performance standards but also significantly reduces waste generated during manufacturing processes. This shift towards sustainable materials not only helps in reducing the reliance on non-renewable resources but also aligns with global sustainability goals.

In addition to material innovations, the adoption of energy-efficient manufacturing technologies is reshaping the landscape of bearing production. Factories are leveraging smart manufacturing techniques, such as IoT and AI, to optimize energy consumption and reduce emissions throughout the production cycle. By focusing on energy efficiency and waste reduction, manufacturers can enhance their operational sustainability while remaining competitive in a rapidly evolving market. As these trends continue to evolve, the precision bearing industry is set to lead the way in sustainable manufacturing practices, fulfilling the needs of global buyers seeking both quality and environmental responsibility by 2025.

Global Export Strategies: China's Competitive Edge in Precision Bearings by 2025

China's position in the global precision bearings market is becoming increasingly pivotal as we look towards 2025. With a market size predicted to grow significantly, from USD 50.16 billion in 2025 to USD 97.10 billion, strategic export initiatives will play a crucial role in reinforcing China's competitive edge. Leveraging advanced manufacturing techniques and a robust supply chain infrastructure, Chinese manufacturers can cater to diverse global demands, meeting the requirements for high precision and reliability in various industries.

Tip: Focus on continuous innovation and investment in R&D to stay ahead in quality and technology. As competition intensifies, companies must ensure that they adopt the latest technologies to enhance their production capabilities and product offerings.

In addition to technology, understanding global buyers' preferences and regional market trends will be essential. By tailoring products to specific industries such as automotive, aerospace, and robotics, Chinese exporters can solidify their leadership in the precision bearings sector.

Tip: Engage with international partners and participate in global trade shows to gain insights and establish valuable connections. Building relationships with key players in other countries will facilitate knowledge sharing and pave the way for competitive collaborations.