Exploring Innovative Applications of Best Miniature Ball Bearings in Diverse Industries

Miniature ball bearings are essential components utilized across a myriad of industries, enabling precision and efficiency in various applications. According to a report by TechNavio, the global miniature ball bearings market is expected to grow at a CAGR of 5.2% from 2021 to 2025, reaching a value of approximately $900 million by the end of the forecast period. This growth is driven by the increasing demand for compact and lightweight machinery in sectors such as aerospace, automotive, medical devices, and electronics. As industries continue to innovate and strive for higher performance standards, the versatility and reliability of miniature ball bearings are becoming more crucial.

This blog will explore the innovative applications of these components, highlighting how they optimize performance and contribute to advancements in technology across diverse fields.

Innovative Miniature Ball Bearings: Overview of Essential Features and Benefits

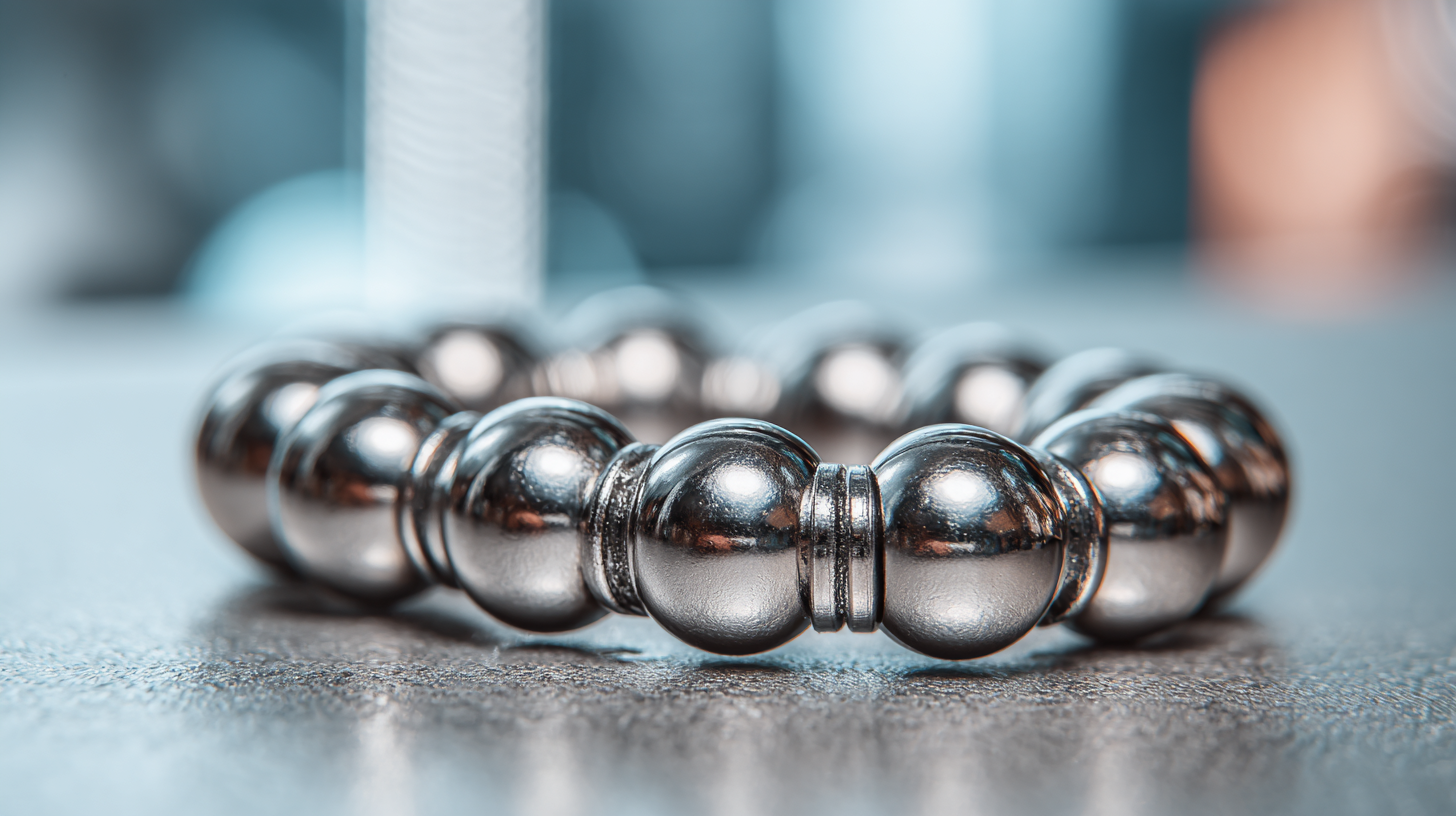

Miniature ball bearings have gained significant traction across a variety of industries due to their unique features and multifaceted benefits. These compact components are engineered to support both radial and axial loads while minimizing friction, which ultimately enhances operational efficiency. With sizes often as small as a few millimeters in diameter, they can be seamlessly integrated into designs where space is at a premium, such as in precision machinery, electronics, and medical devices.

The advantages of innovative miniature ball bearings extend beyond mere size. Their advanced construction allows for smoother rotation, quieter operation, and increased durability under stress. The materials used in their manufacture—ranging from stainless steel to advanced polymers—offer resistance to corrosion and wear, making them suitable for demanding environments. As industries continue to prioritize efficiency, reliability, and innovation, these miniature ball bearings are positioned to play a crucial role in advancements spanning diverse sectors, including automotive, aerospace, and robotics.

Exploring Innovative Applications of Best Miniature Ball Bearings in Diverse Industries

| Industry |

Application |

Essential Features |

Benefits |

| Automotive |

Wheel Assemblies |

High Load Capacity, Low Friction |

Enhanced Performance, Fuel Efficiency |

| Aerospace |

Actuators |

Corrosion Resistance, Precision Engineering |

Reliability, Safety in Flight |

| Medical |

Surgical Equipment |

Compact Size, Easy to Sterilize |

Improved Hygiene, Precision Operation |

| Electronics |

Hard Disk Drives |

Minimal Noise, Smooth Operation |

Data Reliability, User Experience |

| Robotics |

Joint Mechanisms |

Durability, Low Temperature Operation |

Increased Longevity, Efficiency |

Key Industries Utilizing Miniature Ball Bearings for Enhanced Performance

Miniature ball bearings play a crucial role across various industries, enhancing the performance of products in sectors such as robotics, medical devices, and consumer electronics. The global miniature bearings market is projected to reach $4.7 billion by 2027, growing at a CAGR of 7.5% from 2020 to 2027, as reported by a recent market analysis. Robotics, in particular, has seen a surge in demand for these components due to the increasing automation in manufacturing processes. Miniature ball bearings enable precision movement and reduce friction, making them essential for robotic arms and automated machinery to perform tasks with high accuracy.

In the medical device industry, miniature ball bearings are vital for the operation of equipment like surgical tools, imaging devices, and prosthetics. According to the Medical Device Innovation Consortium, the demand for compact and efficient components is driving innovations in bearing design, which aim to meet the growing need for precision and reliability in healthcare applications. Additionally, in consumer electronics, small form-factor devices such as smartphones and drones require lightweight, durable bearings to ensure optimal performance and longevity. The integration of advanced materials and manufacturing techniques continues to propel the use of miniature ball bearings in these high-tech applications.

Comparative Analysis: Different Types of Miniature Ball Bearings and Their Applications

Miniature ball bearings are crucial components in various industries, offering distinct advantages depending on their specific designs. The primary types of miniature ball bearings include deep groove, angular contact, and thrust ball bearings.

Deep groove bearings are known for their versatility and ability to handle radial and axial loads, making them ideal for electric motors and gears. Angular contact bearings, on the other hand, excel in applications requiring high-speed performance and precise alignment, often utilized in CNC machinery and robotics. Finally, thrust ball bearings are designed for handling axial loads, perfect for applications in automotive and aerospace sectors where thrust forces are prevalent.

Deep groove bearings are known for their versatility and ability to handle radial and axial loads, making them ideal for electric motors and gears. Angular contact bearings, on the other hand, excel in applications requiring high-speed performance and precise alignment, often utilized in CNC machinery and robotics. Finally, thrust ball bearings are designed for handling axial loads, perfect for applications in automotive and aerospace sectors where thrust forces are prevalent.

Tips for selecting the right type of miniature ball bearing include considering the operating environment and load conditions. For instance, if your application involves high speeds, opt for angular contact designs to minimize friction and heat generation. Additionally, ensure proper lubrication to extend the lifespan of the bearings. Regularly inspecting and maintaining the bearings can prevent failure and downtime in critical machinery.

Lastly, weight and size constraints should not be overlooked. Smaller bearings can reduce the overall weight of assemblies and improve efficiency, so consider how miniature ball bearings can enhance both performance and form factor in your design.

Challenges and Solutions in Implementing Miniature Ball Bearings Across Sectors

The implementation of miniature ball bearings across various sectors presents both significant challenges and innovative solutions. As industries embrace digital transformation under Industry 4.0, the demand for high-performance bearings is surging. The global miniature ball bearings market is expected to reach USD 2.25 billion by 2025, reflecting a robust growth trajectory that aligns with advancements in manufacturing technologies. However, integrating these components effectively often faces obstacles such as precision manufacturing requirements and material fatigue over time.

To address these challenges, companies are increasingly investing in advanced materials and smart technology. Utilizing deep learning-based approaches can enhance machinery health management, allowing for proactive maintenance and fault diagnosis, which is crucial in resource-constrained environments. For instance, as the automotive industry shifts toward electrification, it necessitates innovative bearing technologies that can withstand new operational demands without compromising efficiency.

Tips:

1. Ensure rigorous testing of miniature ball bearings to improve their reliability and lifespan under varying operating conditions.

2. Integrate predictive maintenance strategies with intelligent sensors to monitor the health of ball bearings in real-time, minimizing unexpected downtimes.

Future Trends: Advancements in Miniature Ball Bearing Technology and Its Impact on Industries

The miniature ball bearing industry is witnessing remarkable transformations driven by advancements in technology. As we look toward the future, the automotive sector stands out with its substantial growth projections. The automotive ball screw market, valued at $494.47 million in 2024, is expected to reach $624.31 million by 2032, reflecting a steady growth rate of 2.9%. This surge highlights the increasing reliance on precision-engineered components that enhance vehicle performance and efficiency.

Similarly, the global automotive bearing market is on an upward trajectory. With a market size of $14.76 billion in 2023, it's projected to grow to $21.38 billion by 2032. This growth not only signifies the rising demand for advanced technologies in vehicle manufacturing but also emphasizes the role of miniature ball bearings in various applications, from electric vehicles to traditional combustion engines.

Tips: When considering miniature ball bearings for your projects, prioritize quality and durability to ensure long-lasting performance. Regularly assess your supplier's technology updates to stay ahead in a competitive landscape. Additionally, explore collaborations with engineers to tailor solutions that best meet your industry’s specific needs.