7 Expert Tips for Maintaining Your Split Bearing Efficiency

In the world of industrial machinery, the efficiency of components is crucial for optimizing performance and reducing operational costs. One key component that often plays a pivotal role in machinery longevity and function is the split bearing. These bearings, designed for easy installation and maintenance, can significantly enhance the performance of rotating equipment when properly cared for. However, maintaining split bearing efficiency requires more than just regular checks; it involves a strategic approach to lubrication, alignment, and monitoring. In this blog, we will explore seven expert tips that will help you maximize the efficiency and lifespan of your split bearings. Whether you're an equipment manager, maintenance technician, or simply someone looking to get the most out of your machinery, these insights will guide you toward achieving peak performance in your operations.

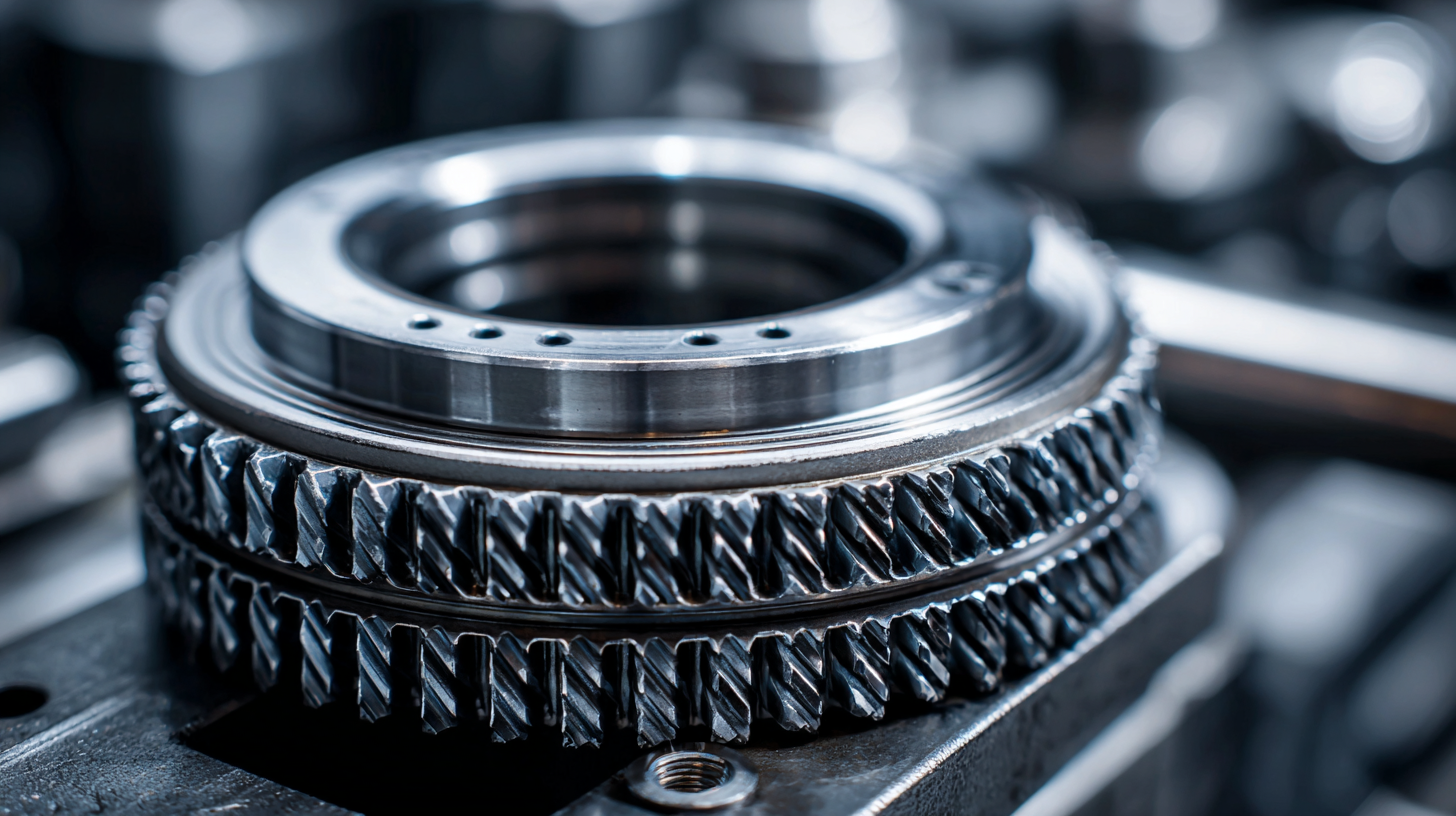

Understanding Split Bearings and Their Importance in Machinery Performance

Split bearings play a crucial role in the efficiency and longevity of machinery. They allow for easier installation and maintenance, which helps minimize downtime. Understanding the importance of these components can significantly impact overall machinery performance.

By ensuring that split bearings are in optimal condition, businesses can avoid costly repairs and improve operational reliability.

Split bearings play a crucial role in the efficiency and longevity of machinery. They allow for easier installation and maintenance, which helps minimize downtime. Understanding the importance of these components can significantly impact overall machinery performance.

By ensuring that split bearings are in optimal condition, businesses can avoid costly repairs and improve operational reliability.

One of the most effective tips for maintaining split bearing efficiency is regular lubrication. Adequate lubrication reduces friction and wear, extending the lifespan of the bearings. Additionally, implementing a strict monitoring system for temperature and vibration levels can help detect potential issues early, allowing for timely interventions. Regular inspections are also crucial; checking for misalignment or signs of wear can prevent larger problems from developing.

Another important tip is to use the right tools for installation and alignment. Improper installation can lead to premature failure, so always follow specified guidelines. Furthermore, ensuring that the surrounding environment is clean and free from contaminants will protect the split bearings, allowing them to perform at their best. By incorporating these practices, you can maximize the benefits of split bearings in your machinery.

Key Factors Affecting the Efficiency of Split Bearings

When it comes to maintaining the efficiency of split bearings, several key factors play a pivotal role. First and foremost, proper lubrication is essential. Split bearings operate under significant load and friction; thus, using the right type of lubricant can significantly reduce wear and tear. Regularly monitoring and replenishing the lubricant not only prolongs the service life of the bearings but also ensures smooth operation, preventing overheating and potential failure.

Another critical factor is the alignment of the split bearings. Misalignment can lead to uneven wear and loading, resulting in decreased efficiency over time. It is crucial to regularly check and adjust the alignment to maintain optimal performance. Additionally, the cleanliness of the working environment should not be overlooked; contaminants can compromise the integrity of the bearings. Implementing a routine cleaning schedule and using protective covers can prevent debris intrusion, further enhancing the longevity and efficiency of split bearings. By focusing on these key factors, you can ensure your split bearings operate at their best.

7 Expert Tips for Maintaining Your Split Bearing Efficiency - Key Factors Affecting the Efficiency of Split Bearings

| Tip |

Description |

Impact on Efficiency |

| Regular Lubrication |

Ensure the bearings are regularly lubricated to reduce friction. |

Improves lifespan and efficiency by minimizing wear. |

| Proper Alignment |

Check and adjust the alignment of split bearings during installation. |

Prevents uneven wear and overheating. |

| Temperature Monitoring |

Regularly check temperatures to identify overheating issues. |

Helps in early detection of potential failures. |

| Vibration Analysis |

Use vibration analysis tools to detect irregularities. |

Identifies potential problems before they escalate. |

| Regular Inspections |

Perform routine inspections to check for wear and tear. |

Maintains operational reliability and efficiency. |

| Use Quality Components |

Invest in high-quality split bearings to enhance performance. |

Directly correlates with durability and efficiency. |

| Correct Load Distribution |

Ensure load is evenly distributed across all bearings. |

Increases overall performance and prevents failures. |

Regular Maintenance Practices to Enhance Split Bearing Lifespan

To ensure the longevity and efficiency of split bearings, regular maintenance practices are crucial. One of the fundamental approaches is conducting routine inspections. Regularly checking for signs of wear, misalignment, or contamination can help identify potential issues before they escalate. Implementing a schedule for these inspections can provide a structured approach, ensuring that no critical components are overlooked.

Additionally, proper lubrication is essential for maintaining optimal performance. Using the right type and amount of lubricant can significantly reduce friction and wear, extending the lifespan of the bearings. It’s vital to adhere to manufacturer guidelines regarding lubrication frequency and methods.

Furthermore, keeping the working environment clean and free from debris can reduce the chances of contamination, safeguarding the integrity of the bearings. Regularly cleaning any external components and seals can also prevent dirt from entering the system, enhancing overall operational efficiency.

Common Issues with Split Bearings and How to Prevent Them

When it comes to split bearings, understanding the common issues that can arise is essential for maintaining their efficiency. One prevalent problem is the breakdown of the bearings due to contamination or improper lubrication. Dirt accumulation can lead to increased wear and tear, drastically affecting the performance of the machinery. To prevent this, it's vital to establish a regular cleaning schedule and ensure that the bearings are adequately lubricated, potentially using water-lubricated systems to minimize oil leak risks.

Another critical issue is the difficulty associated with replacing split bearings, especially when they are in a cramped or trapped position. Traditional methods can be time-consuming and inefficient, leading to extended downtimes. The introduction of innovative solutions designed to simplify the bearing replacement process can be a game changer. This not only reduces the overall maintenance time but also increases the reliability of the equipment, ensuring smoother operations in industrial settings where split bearings are a critical component.

By addressing these common issues proactively, operators can significantly enhance the longevity and performance of their split bearings.

Best Practices for Inspections and Monitoring of Split Bearings

When it comes to maintaining the efficiency of split bearings, regular inspections and monitoring are essential. Start by establishing a routine inspection schedule to identify any potential issues before they escalate. This includes checking for any signs of wear, misalignment, or contamination. Observing temperature variations can also provide insights into the bearing's health. An increase in temperature may indicate friction problems or inadequate lubrication, necessitating immediate attention.

Another best practice for monitoring split bearings is to implement vibration analysis. By using specialized sensors, you can detect irregular vibrations that may suggest imbalance or discrepancies in operation. This proactive approach allows maintenance teams to address problems early on, reducing downtime. Additionally, keeping a detailed record of inspections and any findings enables better analysis over time, helping to understand trends and enhance decision-making related to future maintenance strategies.