Understanding the Essential Role of Roller Bearings in Modern Machinery

In the realm of modern machinery, roller bearings are indispensable components that facilitate smooth and efficient operations across various industries. According to a report by Mordor Intelligence, the global roller bearings market was valued at approximately $30 billion in 2020 and is expected to grow at a CAGR of 4.7% through 2026, driven by the increasing demand for precision machinery and automation.

Roller bearings significantly reduce friction between moving parts, which not only enhances performance but also prolongs equipment lifespan, leading to substantial cost savings for manufacturers. Moreover, advancements in material technology and design have further expanded the application potential of roller bearings in sectors ranging from automotive to aerospace. As industries continue to evolve, the critical role of roller bearings in ensuring reliability and efficiency cannot be overstated, making them a focal point for engineers and manufacturers alike.

Identifying Different Types of Roller Bearings and Their Applications

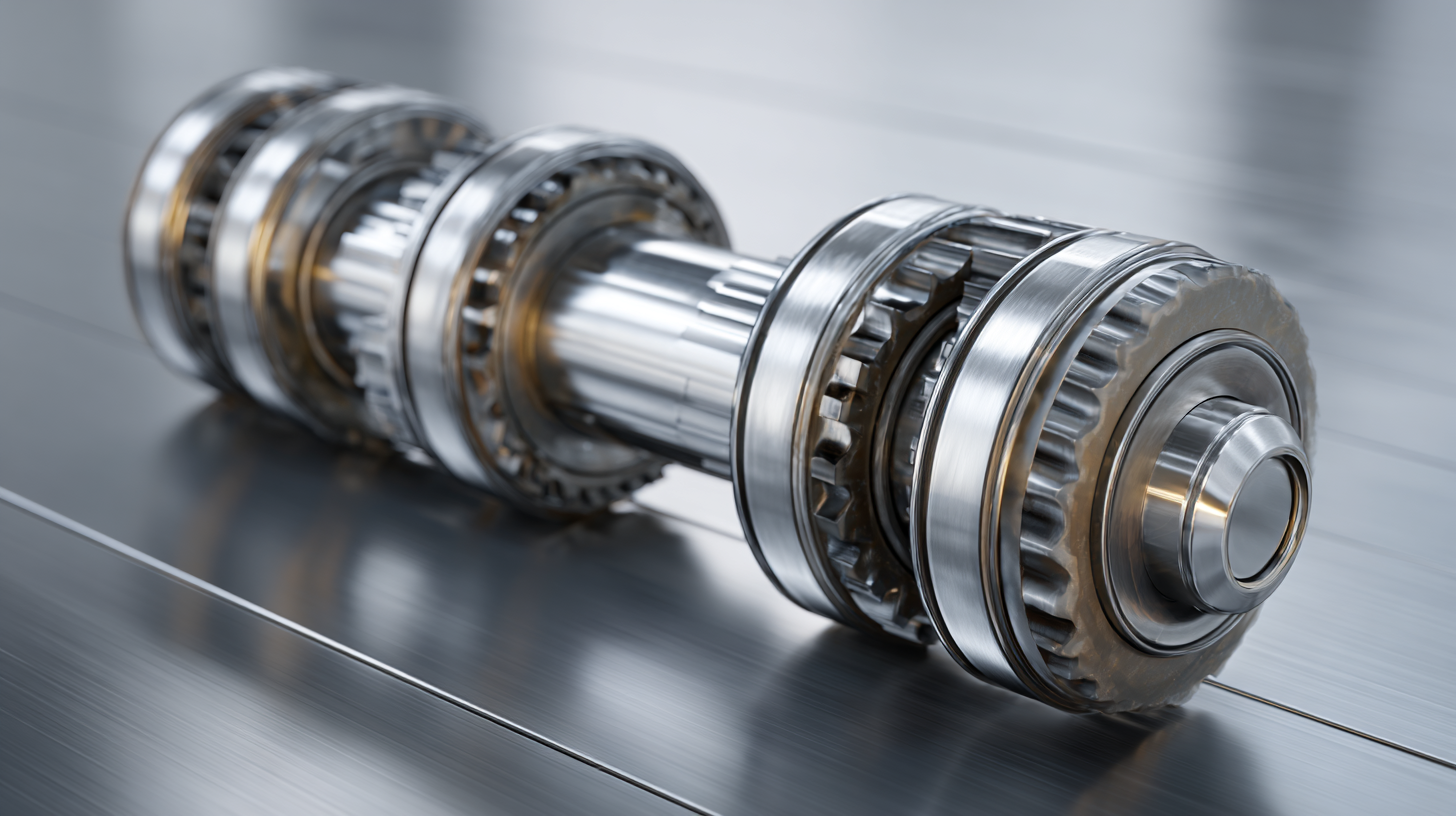

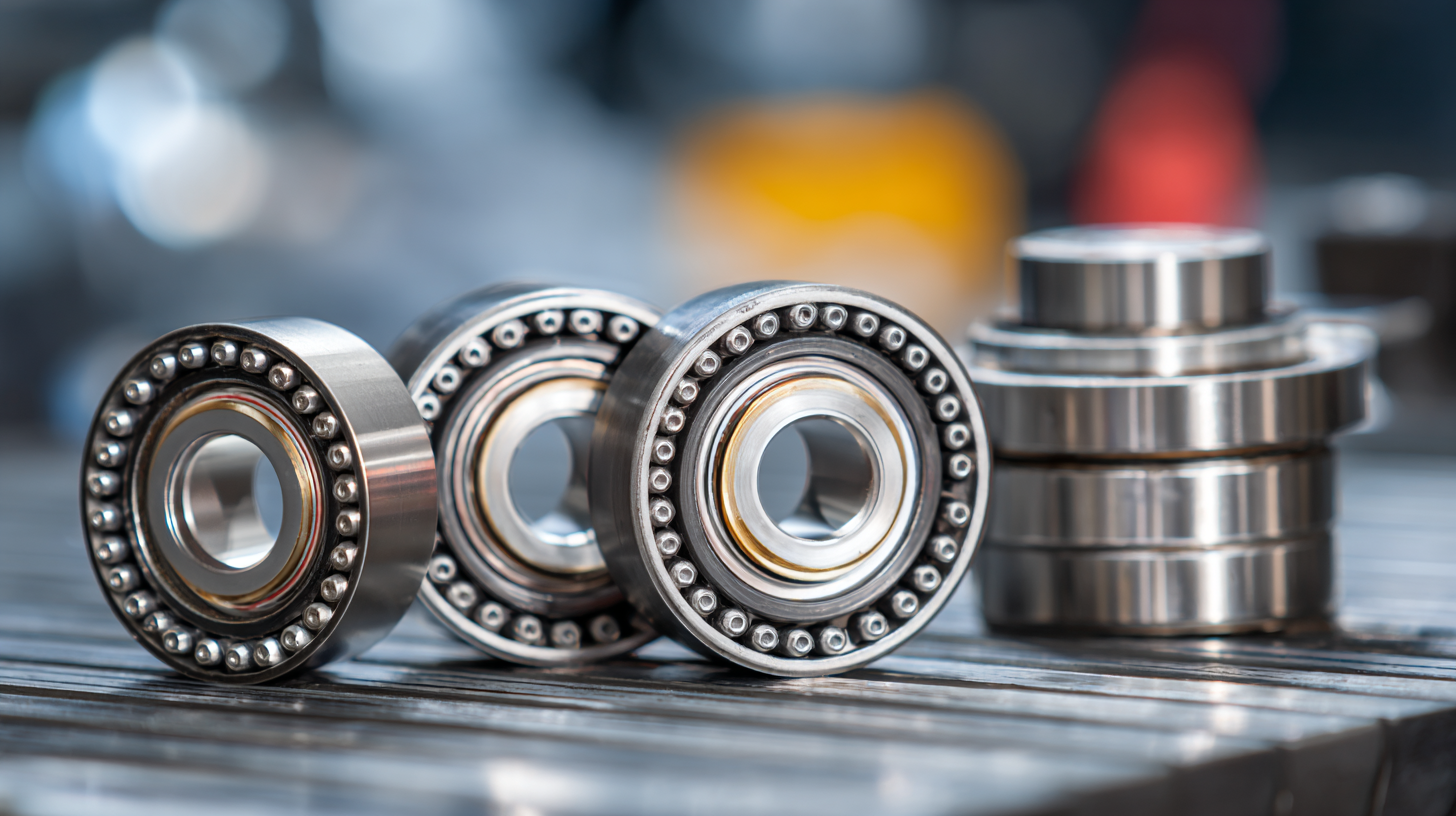

Roller bearings are crucial components in modern machinery, providing enhanced performance and reliability across various applications. There are several types of roller bearings, each designed to handle specific loads and operating conditions. For instance, cylindrical roller bearings are ideal for high radial loads and are commonly used in applications like electric motors and gearboxes, while spherical roller bearings can accommodate misalignment, making them suitable for heavy machinery in mining and construction.

According to a recent market research report, the global roller bearings market is projected to reach USD 28 billion by 2025, driven by the increasing demand for automated machinery and efficient industrial processes. Tapered roller bearings are also gaining traction, particularly in automotive applications, due to their ability to manage both radial and axial loads simultaneously. The versatility and efficiency of roller bearings not only enhance machinery performance but also contribute to reduced maintenance costs, reinforcing their essential role in various sectors, including aerospace and manufacturing.

Understanding the Critical Functions of Roller Bearings in Machinery

Roller bearings play a critical role in modern machinery by significantly reducing friction and wear during operation. They allow for smoother movement and enhanced efficiency in applications ranging from industrial machinery to automotive systems. According to the International Organization for Standardization (ISO), bearing failures account for up to 40% of premature machine breakdowns, highlighting the importance of selecting high-quality roller bearings. The significant advancement in materials and design over recent years has led to improved load capacity and operational lifespans, optimizing machinery performance.

To ensure optimal functionality, consider the following tips when selecting roller bearings for your machinery: First, assess the load requirements and environmental conditions of your application. A study by the American Society of Mechanical Engineers (ASME) indicates that choosing the right bearing type can enhance a machine's productivity by as much as 15%. Secondly, regular maintenance is crucial; lubrication intervals must be adhered to, as 90% of bearing failures are linked to improper lubrication practices. By implementing these strategies, you can prolong the life and reliability of machinery in diverse industrial settings.

Evaluating the Benefits of Roller Bearings in Industrial Settings

Roller bearings play a crucial role in enhancing the efficiency and effectiveness of modern machinery in industrial settings. Their design allows them to accommodate both radial and axial loads, significantly reducing friction between moving parts. This reduction in friction not only improves energy efficiency but also enhances the longevity of the machinery, leading to lower maintenance costs and downtime. Industries that rely on heavy machinery, such as manufacturing and automotive, have particularly benefited from the application of roller bearings, as they enable operations at higher speeds and loads without the risk of premature failure.

Moreover, roller bearings contribute to precision and stability in various industrial applications. Their ability to maintain consistent alignment under load helps in ensuring that components function smoothly, which is essential in high-performance environments. With the growing demand for automation and increased production rates, the advantages offered by roller bearings, such as improved accuracy and reliability, make them indispensable in modern machinery. By adopting roller bearing technology, industries can bolster their operational capacities, resulting in enhanced productivity and competitiveness in the market.

Maintenance Tips for Enhancing Roller Bearing Performance

Proper maintenance of roller bearings is crucial for ensuring their performance and longevity in modern machinery. Regular inspection is essential; operators should routinely check for signs of wear, such as discoloration or pitting on the bearing surfaces. Additionally, keeping bearings clean and free from contaminants can significantly enhance their efficiency. Utilizing proper sealing solutions can help minimize the ingress of dirt and moisture that could lead to premature failure.

Lubrication also plays a vital role in maintaining roller bearing performance. It’s important to choose the right type of lubricant based on the operating conditions and to adhere to the manufacturer’s recommendations for lubrication intervals. Over-lubrication as well as under-lubrication should be avoided, as both can lead to increased friction or overheating. Implementing a systematic maintenance schedule, along with training personnel in best practices, can contribute to the overall reliability of roller bearings in machinery.

Understanding the Essential Role of Roller Bearings in Modern Machinery - Maintenance Tips for Enhancing Roller Bearing Performance

| Aspect |

Details |

| Type of Roller Bearing |

Ball Bearings, Cylindrical Bearings, Spherical Bearings, Tapered Bearings |

| Load Capacity |

Varies by type: typically ranges from hundreds to thousands of pounds |

| Common Applications |

Automotive, Industrial Machinery, Aerospace, Electrical Motors |

| Maintenance Frequency |

Every 3-6 months, depending on the application and conditions |

| Common Issues |

Wear & Tear, Lubrication Failure, Contamination |

| Maintenance Tips |

Regular Inspections, Proper Lubrication, Keeping Environments Clean |

| Lubrication Types |

Grease, Oil, Hybrid Lubricants |

| Lifespan |

Depending on maintenance, typically ranges from 1 to 10 years |

Troubleshooting Common Issues with Roller Bearings in Modern Equipment

Roller bearings play a crucial role in the smooth operation of modern machinery, yet they are not immune to problems that can impact performance. Common issues include improper lubrication, which often leads to increased friction and wear. It's essential to ensure that roller bearings are adequately lubricated with the right type of oil or grease to minimize heat generation. Regularly checking for signs of wear and contamination can also prevent serious complications that might arise from neglect.

Roller bearings play a crucial role in the smooth operation of modern machinery, yet they are not immune to problems that can impact performance. Common issues include improper lubrication, which often leads to increased friction and wear. It's essential to ensure that roller bearings are adequately lubricated with the right type of oil or grease to minimize heat generation. Regularly checking for signs of wear and contamination can also prevent serious complications that might arise from neglect.

Another frequent issue is misalignment, which can cause uneven loading and premature failure of the bearings. To troubleshoot this, regular maintenance checks should include alignment assessments. If misalignment is detected, adjustments should be made promptly to prevent further damage. Additionally, monitoring for vibration and noise can offer early warnings of potential failures, allowing for proactive measures to be taken. By addressing these common issues, the longevity and efficiency of roller bearings in modern equipment can be significantly enhanced.