Unlocking Efficient Machinery: How a Bearing Finder Can Revolutionize Your Maintenance Strategy

In the ever-evolving landscape of industrial maintenance, the advent of technology has paved the way for innovative solutions designed to enhance operational efficiency. One such breakthrough is the bearing finder, a tool that not only simplifies the identification of bearings but also significantly optimizes maintenance strategies.

According to a report by the International Society of Automation, improper bearing maintenance contributes to up to 40% of equipment failures, leading to substantial downtime and financial losses for businesses. The implementation of a bearing finder can mitigate these risks by providing precise data on bearing specifications, thereby facilitating timely maintenance and reducing unplanned outages. By embracing this digital innovation, companies can revolutionize their maintenance practices, ultimately extending the lifespan of their machinery and achieving a competitive edge in the market.

According to a report by the International Society of Automation, improper bearing maintenance contributes to up to 40% of equipment failures, leading to substantial downtime and financial losses for businesses. The implementation of a bearing finder can mitigate these risks by providing precise data on bearing specifications, thereby facilitating timely maintenance and reducing unplanned outages. By embracing this digital innovation, companies can revolutionize their maintenance practices, ultimately extending the lifespan of their machinery and achieving a competitive edge in the market.

The Role of Bearings in Machinery Efficiency and Maintenance

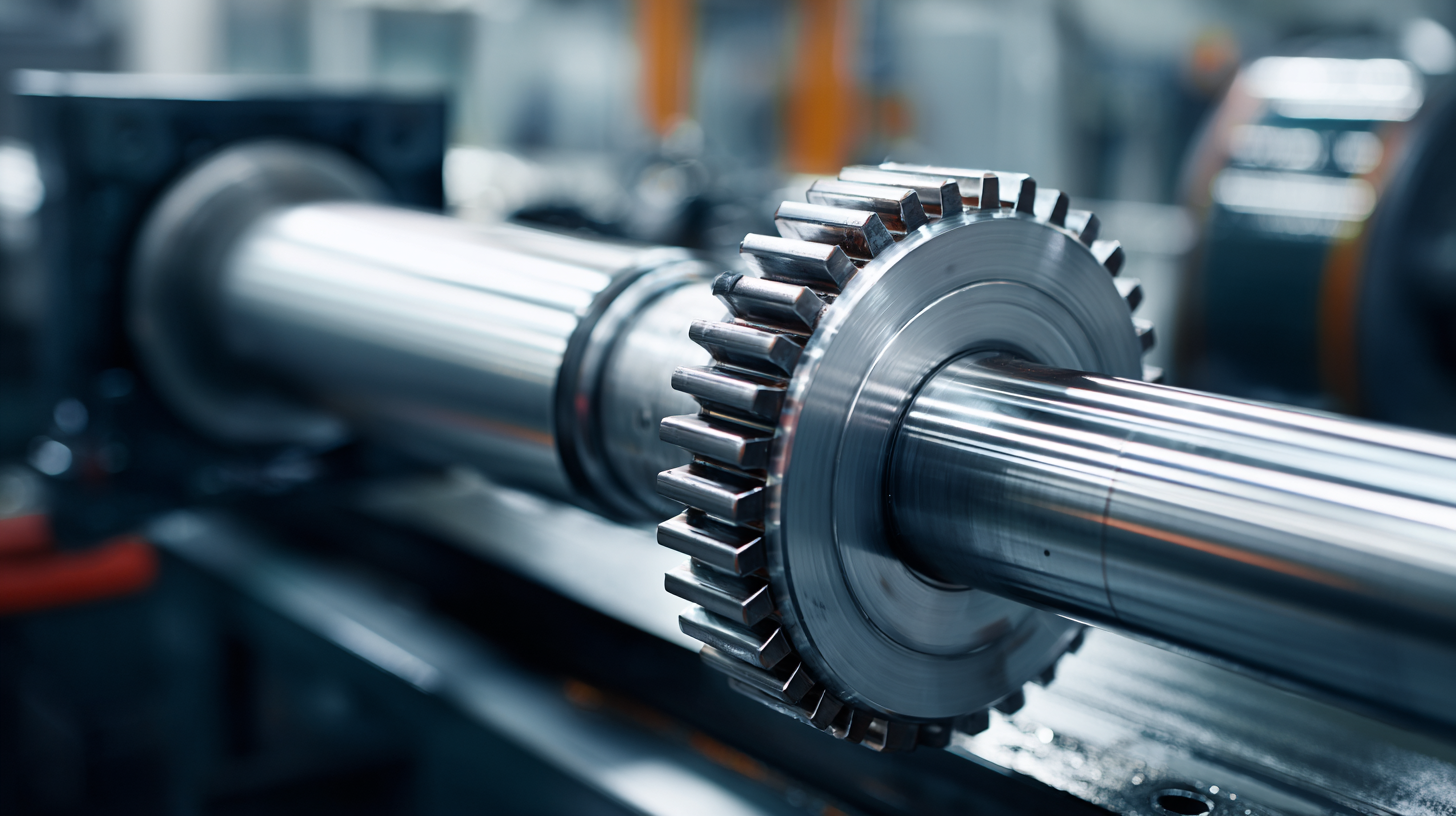

Bearings are crucial components in machinery that facilitate smooth motion and reduce friction between moving parts. Their efficiency directly impacts the overall performance of machines, influencing not only operational productivity but also energy consumption. By enabling better load distribution and minimizing wear and tear, high-quality bearings contribute significantly to extending equipment lifespan and decreasing the frequency of repairs.

A strategic maintenance approach that includes a bearing finder can enhance machinery efficacy tremendously. This tool allows for the precise identification and selection of bearings tailored to specific machinery requirements, ensuring optimal performance. With accurate bearings in place, machines can operate more reliably, thus reducing downtime and maintenance costs. Effective bearing management ultimately leads to a more sustainable operation, as it fosters proactive maintenance practices that can preempt failures and enhance the reliability of machinery across various industries.

Understanding the Different Types of Bearings and Their Applications

Bearings are critical components in machinery, significantly influencing operational efficiency and maintenance practices. There are several types of bearings, including roller bearings, ball bearings, and plain bearings, each with unique applications. According to a report by MarketsandMarkets, the global bearing market is projected to reach $100.98 billion by 2025, driven by technological advancements in these essential parts. For instance, while ball bearings are best for high-speed applications due to their reduced friction, roller bearings excel in handling heavy loads, making them suitable for heavy machinery.

Tips: When selecting bearings for your equipment, consider their load ratings and speed capabilities to enhance performance. Ensure regular inspections as well; bearing failure accounts for approximately 40% of all equipment failures, as highlighted in a report by the Reliabilityweb.com.

Understanding the diverse types of bearings can also aid in predicting maintenance needs. For example, magnetic bearings offer non-contact support, which minimizes wear and tear, significantly extending service life. Implementing a bearing finder tool can streamline this process, allowing maintenance teams to quickly identify and acquire the suitable bearing type for specific machinery, thereby revolutionizing overall maintenance strategies.

Understanding the Different Types of Bearings and Their Applications

Implementing a Bearing Finder for Streamlined Maintenance Processes

In today’s fast-paced industrial landscape, maintaining machinery efficiently is crucial for maximizing productivity.

Implementing a bearing finder can significantly streamline maintenance processes, turning a traditionally labor-intensive task into a swift and precise operation.

With the ability to identify the specific type and size of bearings needed, a bearing finder reduces downtime and enhances equipment reliability.

Tips for successful implementation include: First, ensure that all maintenance personnel are trained on how to utilize the bearing finder effectively, as user familiarity is key to optimizing its benefits.

Second, integrate the tool into your existing maintenance management system to allow for real-time updates and tracking of bearing inventory.

Lastly, regularly update the database of bearings to include new models and variations, ensuring that your team has access to the latest information.

By leveraging cutting-edge technology, businesses can drive operational efficiencies. Just as many leading corporations have utilized AI solutions to transform their processes, adopting a

bearing finder can position your maintenance strategy for success in an increasingly competitive market.

Investing in such innovations empowers teams to respond faster to challenges and enhances overall machinery performance.

Enhancing Equipment Lifespan Through Proper Bearing Selection

When it comes to maximizing the lifespan of your machinery, proper bearing selection is critical. Bearings play a vital role in the efficiency and functionality of your equipment, and choosing the right type can lead to significant improvements in performance. The right bearing not only enhances operational effectiveness but also minimizes wear and tear, resulting in fewer breakdowns and lower maintenance costs.

Tips: Always assess the operating conditions of your machinery, including load capacity, speed requirements, and environmental factors. This approach will help you identify the most suitable bearing type for your application. Additionally, consider using a bearing finder tool to streamline the selection process. This can save you time and ensure you make informed decisions tailored to your specific machinery needs.

By focusing on the right bearing for your equipment, you're not just ensuring smooth operations; you're also investing in its longevity. Regularly revisiting your bearing choices based on machinery performance can lead to ongoing improvements in maintenance strategies, ultimately unlocking greater efficiency in your operations.

Case Studies: Successful Maintenance Strategies Using Bearing Finders

In recent years, the incorporation of bearing finders into maintenance strategies has shown remarkable benefits across various industries. A case study by the Machinery Maintenance Journal highlighted that companies utilizing advanced bearing finders reported a 30% reduction in unscheduled downtime. With the predictive maintenance capabilities of these tools, maintenance teams can identify potential issues before they escalate, thus saving both time and costs associated with machinery failures.

Another compelling example comes from a large-scale manufacturing facility that integrated bearing finders into their operational routine. According to a report by the Association for Manufacturing Technology, the facility experienced a notable 25% decrease in maintenance costs over the span of a year. This was largely attributed to the early detection of bearing wear and the optimized scheduling of maintenance tasks, facilitating a more efficient allocation of resources and minimizing production interruptions. As industries continue to embrace digital solutions, the role of bearing finders will undoubtedly play a central part in shaping modern maintenance strategies.

Unlocking Efficient Machinery: How a Bearing Finder Can Revolutionize Your Maintenance Strategy

| Case Study |

Industry |

Previous Downtime (hrs/year) |

Post-Implementation Downtime (hrs/year) |

Savings (USD/year) |

Bearing Finder Used |

| Manufacturing Plant A |

Manufacturing |

200 |

50 |

30,000 |

Advanced Bearing Locator |

| Construction Site B |

Construction |

150 |

30 |

25,000 |

Smart Bearing Finder |

| Energy Facility C |

Energy |

300 |

80 |

100,000 |

Pro Bearing Detection System |

| Logistics Company D |

Logistics |

100 |

20 |

15,000 |

Compact Bearing Analyzer |